Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

If the lithium-sulfur battery is the next-generation lithium battery to replace the lithium-ion battery, then the lithium-air battery will be the final form of lithium battery.

From the birth of lithium batteries to the application of just a few decades, the battery industry has gradually replaced fossil energy. In particular, power supply and 3C equipment have a constant demand for lithium-ion batteries. The current LiCoO2 material (theoretical specific capacity 275mAh / g) has always restricted the development and application of lithium-ion batteries. In the current commercial development, Tesla and BYD, as the leading industries of electric vehicles, respectively selected ternary cathode materials and LiFePO4 as cathode materials for lithium ion batteries. But Tesla still uses the 18650 batteries provided by Panasonic, and the above thousands of batteries are assembled into battery packs to power the car. Similarly, LiFePO4 has a theoretical capacity of only 170 mAh/g and a low tap density. BYD's cars are mostly in a transitional state of hybrid power. On May 10, 2016, BYD said on the investor interaction platform that the company's future plug-in hybrid vehicles will try to use ternary lithium batteries. The well-received iphone 6S is also controversial due to the 1715mAh battery, and the later launch of the iPhone 6s Smart Battery Case is a shortcoming of Apple's power supply.

At present, there is an urgent need for a new high-performance battery. In 2012, Professor Peter George Bruce of Oxford University issued a report in Nature that the new generation of high-performance batteries are lithium-sulfur batteries and lithium-air batteries. If the lithium-sulfur battery is the next-generation lithium battery to replace the lithium-ion battery, then the lithium-air battery will be the final form of lithium battery.

Lithium air battery principle

The lithium-ion battery (Li-Air battery) has a positive electrode and a negative electrode of lithium metal. A conventional commercial lithium ion battery with LiCoO2 as a positive electrode has a theoretical specific capacity of 273.8 mAh/g and an energy density of 360 Wh/kg. Since the lithium air battery is an open system, the air electrode has no limit, so the theoretical capacity is larger than other closed batteries. (The non-aqueous energy density is calculated to be 3,505 Wh/kg based on the reaction product Li2O, the water system is 3,582 Wh/kg in LiOH, and the energy density is about ten times that of the LiCoO2 battery)

Lithium air battery electrolytes have different reaction equations:

2Li+ + 2e– + O2→ Li2O2 (non-aqueous electrolyte)

2Li+ + 2e– + ? O2 + H2O → 2LiOH (aqueous electrolyte)

Note: Non-aqueous electrolytes use organic solvents instead of water to dissolve lithium salts. This article is mainly based on non-aqueous systems.

The reaction equation is simpler than LiCoO2 and Li-S, but there are also a series of side reactions in the reaction process. The side reaction products are mainly LiOH and Li2 (CO3). In order to reduce by-products and improve cycle efficiency, researchers mostly react with pure oxygen O2 environment. Therefore, Li-Air battery is also called Li-O2 battery.

Figure 1: Reaction mechanism diagram of LiCoO2 lithium ion battery and Li-O2 battery

A brief history of Li-O2 batteries

Due to the consumption and pollution of fossil fuels such as gasoline, humans need new alternative energy sources. However, the current energy density of lithium-ion battery (LiCoO2 material) 250 Wh/kg is too different from that of gasoline 1750 Wh/kg, which cannot meet daily demand.

1976

The concept of a lithium-air battery was proposed;

1979

KF Blurton, AF Sammells posted on J. Power Sources and highlighted the potential of Zn-Air batteries, and suggested that air batteries can be used in cars.

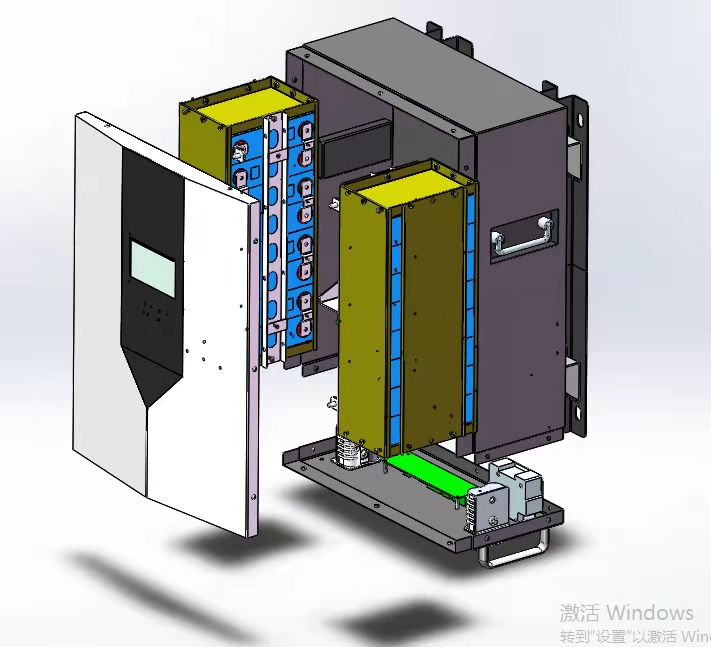

Figure 2: Zn-Air battery structure exploded view

1996

Abraham et al proposed a two-reaction equation for a Li-O2 battery system using lithium metal as the negative electrode, carbon adsorption oxygen as the positive electrode, and organic matter (LiPF6) as the electrolyte.

2Li + O2 → Li2O2 (2.96 V) and 4Li + O2 → 2Li2O2 (2.91 V)

year 2006

Bruce et al. demonstrated the reversible conversion of the discharge product Li2O2 using MnO2 as a catalyst.

Figure 3: Endurance and cost price of various types of batteries

Year 2009

IBM launches "Battery500" program, aiming to achieve Li-Air battery-powered car up to 500KM

Research Status of Li-O2 Battery

At present, Li-O2 batteries can only be charged and discharged under laboratory conditions, and they cannot be directly applied to mobile phones or automobiles. But this does not mean that the Li-O2 battery has no application value, and a large number of researchers have made improvements in various aspects, making the Li-O2 battery evolve to a more suitable application.

Cathode material

The positive electrode of the Li-O2 battery is O2, but the CO2 and H2O in the air cause irreversible loss of capacity, and the metal lithium which is directly in contact with air or oxygen is also oxidized instantaneously, and it is difficult to circulate charge and discharge. In order to avoid contact between the lithium sheet and the air, the researchers used reticulated foamed nickel or porous carbon as the skeleton material of the air electrode.

The carbon material has a relatively large specific surface area, which provides a larger loading position for the catalyst, and provides more reactive sites to enhance the effect of the catalyst. The smaller the pore diameter of the carbon material, the larger the specific surface area, but the smaller the pore diameter, the better. Yang et al. compared activated carbon, Super P, XC-72, carbon nanotubes, etc., and the performance of activated carbon with small pore size was better than that of Super P with large pore size. As shown in Fig. 4, if the pore diameter is too small, a large amount of reaction product is deposited to hinder the reaction discharge.

Figure 4: Schematic diagram of the reaction product (Li2O and Li2O2 in the pore size of carbide)

catalyst

Catalysts are essential for Li-O2 batteries. The entire reaction requires sufficient ORR and OER activity, and the current charge and discharge reaction has problems such as insufficient activity and large polarization potential. Therefore, a large number of researchers are looking for and testing suitable catalysts, reducing the polarization potential and promoting the Li-O2 battery reaction.

Precious metal catalyst: (Au, Pt, Pd, etc.)

A precious metal catalyst (precious metal catalyst) is a precious metal material that changes the rate of chemical reaction and does not itself participate in the final product of the reaction. Their d-electron orbitals are not filled, the surface is easy to adsorb reactants, and the strength is moderate, which is conducive to the formation of intermediate "active compounds", has high catalytic activity, and also has comprehensive excellent properties such as high temperature resistance, oxidation resistance and corrosion resistance. Become the most important catalyst material. The precious metal particles are supported on the positive electrode substrate. As a catalyst, the polarization potential of the Li-O2 battery can be effectively reduced, and the energy efficiency of the battery is improved. Although the ORR performance of the noble metal is good, the OER activity is not high. In addition, precious metal catalysts are expensive and cannot be used on a large scale.

The price of the battery is currently in the range of 200-300 US dollars / kWh, if you can run 5-6 km per kWh, 800 km need a 150 kWh battery, you need 30,000-4.5 million. Therefore, if you want to mass production, the price per kWh must drop below $100.

Oxide catalyst: (Co3O4, MnO2, etc.)

In order to replace precious metal catalysts, metal oxide catalysts have been studied. Many studies have found that transition metal phosphides have outstanding electrocatalytic properties. Researcher at the Institute of Nanotechnology, Chinese Academy of Sciences, Wang Qiangbin, combined the formation of urchin-like cobalt phosphide (CoP) nanocrystals as an ORR electrocatalyst. Oxide catalysts are not as stable in temperature as precious metals, and cycle life needs to be considered. Due to the short development time, these problems have not been solved well by researchers.

Figure 5: Sea urchin CoP catalyst

Oxide catalysts are a solution, but not a perfect solution.

to sum up

At present, Li-O2 batteries can only be charged and discharged in the laboratory, but not for large-scale commercial applications. On the one hand, because of the positive electrode material and the catalyst, the long-acting, large-rate charge and discharge process cannot be achieved. On the other hand, the electrolyte of the open system is exposed, and most organic solvents are toxic and volatile. Imagine that when no one wants to use a mobile phone, there is an electrolyte everywhere.

Most importantly, the lithium-air battery is an extremely cost-burning activity even in research, so that everyone can use the air battery, and the cost compression will take a long time to transition.

I believe that in the near future, Li-O2 batteries will completely change the development of the energy industry when performance and cost are all within an acceptable range. At that time, the Li-O2 battery will change life and rewrite history like the current lithium battery.

November 20, 2023

この仕入先にメール

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.